About Five Finger

Five Finger, located in the East Lake High-Tech Development Zone of Wuhan, is a high-tech enterprise specializing in fiber Bragg grating (FBG) technologies. With over 20 years of industry experience, the company delivers highly reliable FBG products and system solutions for optical communication, fiber sensing, fiber lasers, and medical optoelectronics. Its core expertise spans grating design, manufacturing, packaging, and application engineering, enabling stable performance across diverse industrial and research applications.

Company Background & Industry Experience

Five Finger is a high-tech enterprise located in the Wuhan, China. The company specializes in fiber Bragg grating (FBG) technologies, providing high-reliability products and system-level solutions for optical communication, fiber sensing, fiber lasers, and medical optoelectronics. With a strong focus on engineering quality and application performance, Five Finger supports customers across industrial, research, and commercial markets worldwide.

With over 20 years of experience in the fiber Bragg grating industry, Five Finger has developed deep expertise in grating design, manufacturing, packaging technologies, and application engineering. Through continuous technical innovation and close collaboration with industry and research partners, the company delivers stable, consistent, and application-ready FBG solutions across diverse operating environments, and has established a strong reputation for reliability, customization capability, and long-term technical support.

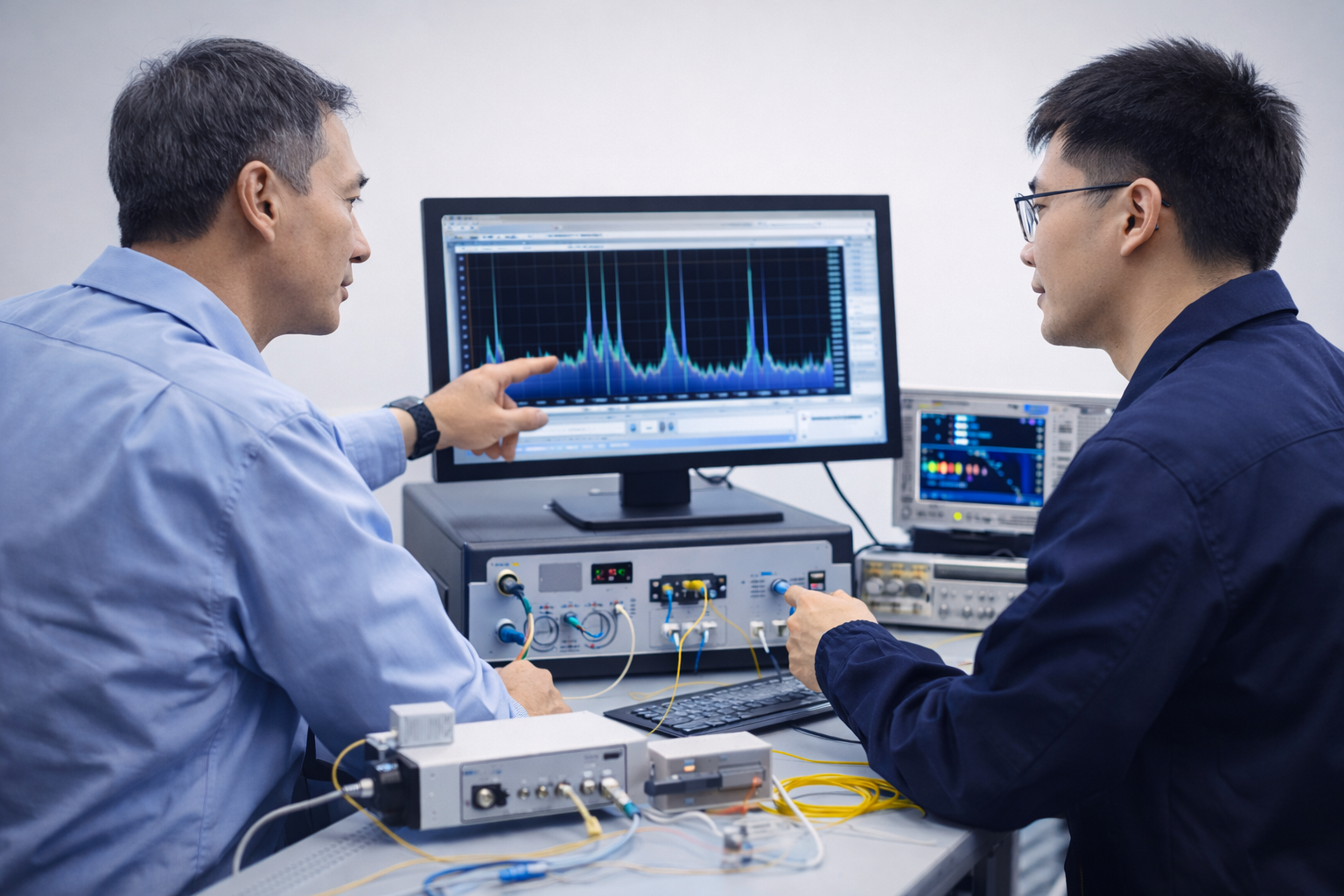

R&D Capabilities & Technical Innovation

Our technical team has over 20 years of experience in the fiber optic and photonics industry, including 10 years focused on research and development. Beyond product design, our tenical team has practical experience across manufacturing, sales, after-sales service, and technical support, giving us a clear understanding of how products perform throughout their full lifecycle.

This end-to-end experience allows us to focus on what matters most to long-term customers: consistent quality, reliable performance, and predictable results across batches. At the same time, our team provides continuous technical support to ensure smooth integration and long-term reliability.We are not a one-time product supplier, but a long-term partner committed to reducing after-sales issues, maintaining supply stability, and supporting sustainable business growth. This approach enables our customers to operate with confidence and build reliable, repeatable solutions for their markets.

Production Capacity

We currently operates 10 fiber Bragg grating production lines, covering major manufacturing stages including FBG writing, testing, packaging, and component assembly. The production facilities are configured with advanced imported equipment from Germany and Japan, supporting batch production and the manufacturing of various types of fiber Bragg grating products.

In key process stages, the production and testing workflow is equipped with German MLI excimer laser systems, YOKOGAWA optical spectrum analyzers, Ibsen photonics phase masks from Denmark, and Fujikura fusion splicers from Japan. These systems are applied to FBG writing, spectral measurement, grating period control, and fiber splicing processes, covering the main manufacturing flow from grating fabrication to final inspection and packaging, and supporting the production of FBG products across different wavelength ranges, structures, and application formats.

Production Capacity

Pre-sales Customer Service

Our comprehensive support services encompass pre-sales consultation, technical training, installation guidance, and ongoing maintenance support. Our experienced technical team provides expert consultation to help customers select the optimal solutions for their specific applications.

We pride ourselves on delivering prompt, professional support that ensures our customers can maximize the performance and reliability of their fiber Bragg grating systems. Our global support network guarantees timely assistance wherever our products are deployed.

Quality Assurance

Quality Control

All products undergo 100% inspection before delivery, with key parameters verified against customer-defined requirements to ensure consistency and application readiness.At the same time, critical production processes are placed under direct technical control, rather than relying solely on routine manual operation. This reduces process variability and helps maintain stable quality across different batches and custom configurations.

In addition, advanced equipment from well-established brands is used to support stable and repeatable performance, enabling tight process control and long-term reliability in real operating environments,reduce quality risk and minimize after-sales concerns.

100% inspection before delivery

Every product is fully inspected against customer-defined specifications to ensure consistency, accuracy, and application readiness before shipment.

Technical control at critical processes

Key production steps are directly supervised and controlled by experienced technical staff to minimize variability and ensure stable quality.

Well-known Brands Equipment for Stable Performance

These systems ensure precise control and consistent quality across all key FBG production stages, from grating writing and spectral measurement to final inspection and packaging.

Ready to Partner with Us?

Discover how our fiber Bragg grating solutions can enhance your projects. Contact our technical team for expert consultation and customized solutions.